Field tests for tomorrow’s agricultural machine vision systems

Demands on agricultural machines are increasing with extraordinary speed. To not only meet but exceed these demands, we conduct field tests under rough real-world conditions already during the development phase. MEKRA Lang is setting trends and driving innovation in this area as well. We develop and manufacture our standardized products based on proven concepts and in cooperation with the original equipment manufacturers (OEMs).

Requirements

In addition to the standards EU 167/2013 and ISO 5721-2 there are regulations governing front-mounted implements according to the German Agricultural Association DLG. Our mirror and camera monitor systems meet all of the relevant provisions.

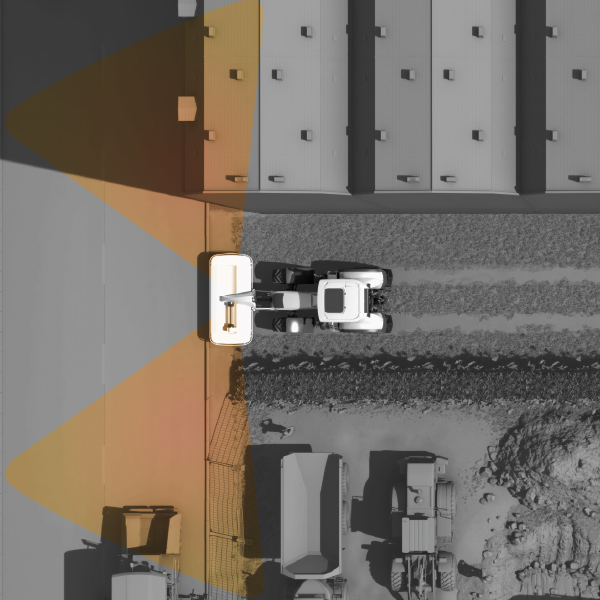

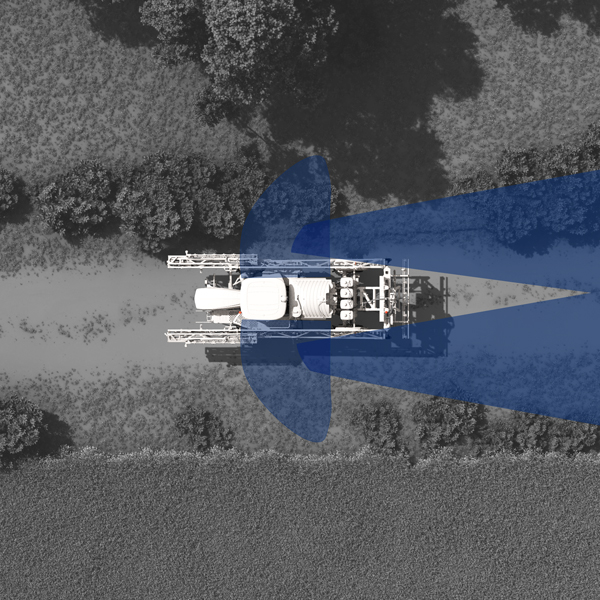

The statutory fields of view represent minimum requirements. The MEKRA fields of vision shown in ideal-typical representation may vary depending on vehicle size, shape, and mounting location. They do, however, always meet the legal minimum requirements.

Field of vision behind the farm tractor

The field of vision behind the farm tractor is located one meter above the ground. It starts four meters behind the so-called

“seat index point” (SIP) at a width of one meter directed outwards from the outer vehicle edge. The length is an additional 26 meters towards the back, the width thereby extending to five meters. From this point the horizon still has to be visible.

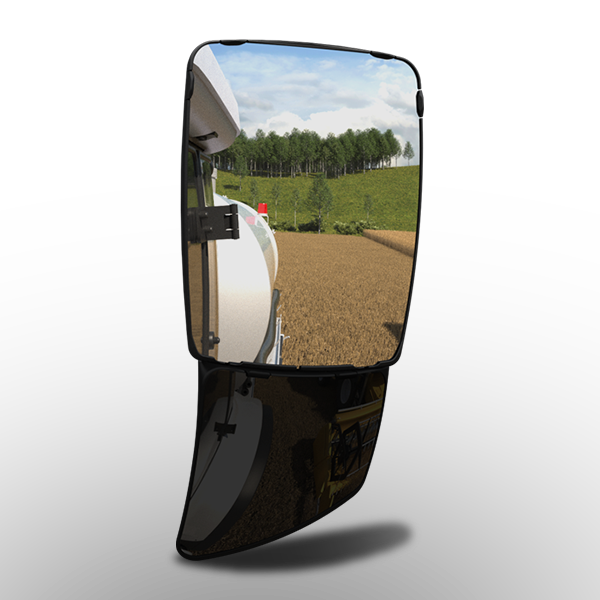

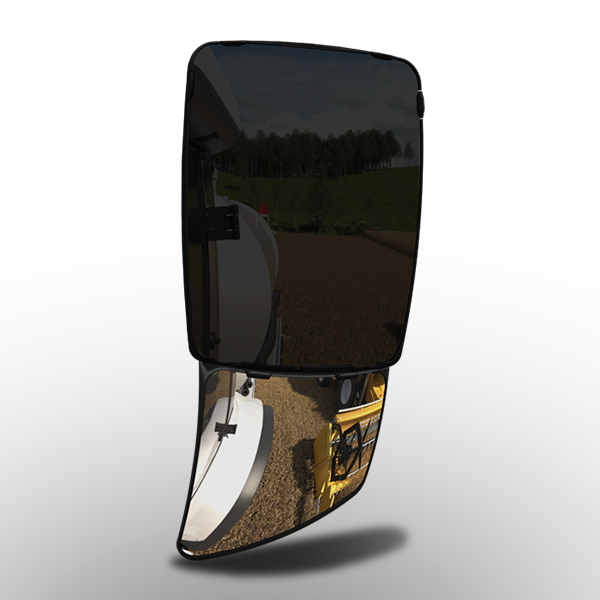

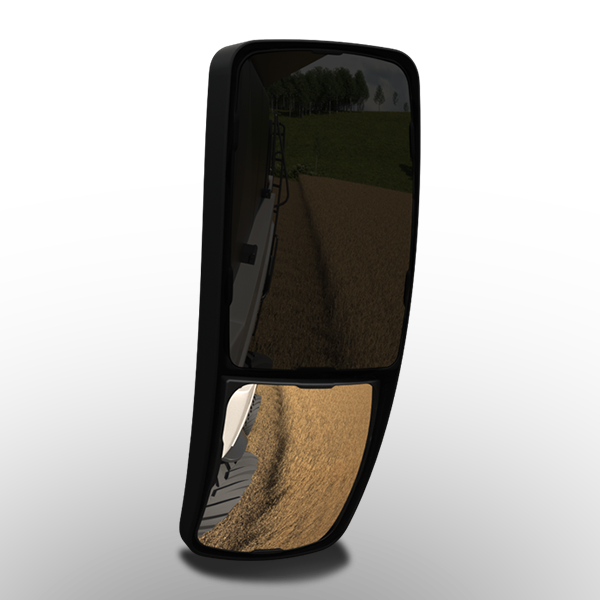

Mirror Solution

A traditional solution would be a so-called main mirror with a radius of curvature of 1200 mm.

We offer this type of mirror (e.g. no. 1009) in a number of configurations, including manually adjustable, heated or also electrically adjustable.

Camera Solution

Field of vision to the side of the farm tractor

This field of vision is one meter above the ground and starts 0.5 m from the outermost vehicle outline. At eye point height it then extends by 1.75 m towards the back and by 1 m to the front. It is 1.5 m towards the outside.

It is important to note that either 90 % of this field of vision must be visible directly or 100 % by a combination of direct and indirect vision.

Mirror Solution

MEKRA Lang has developed a variety of solutions to meet these requirements.

Among other options, the 1009 modular mirror or the 1036 combination mirror can be used.

Camera Solution

An additional innovative solution would be viewing the field of vision with a camera which could be attached to the 1009 modular mirror as an add-on.

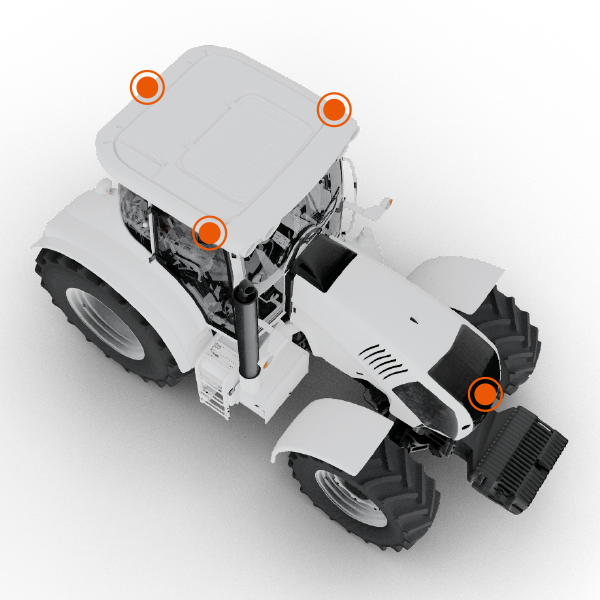

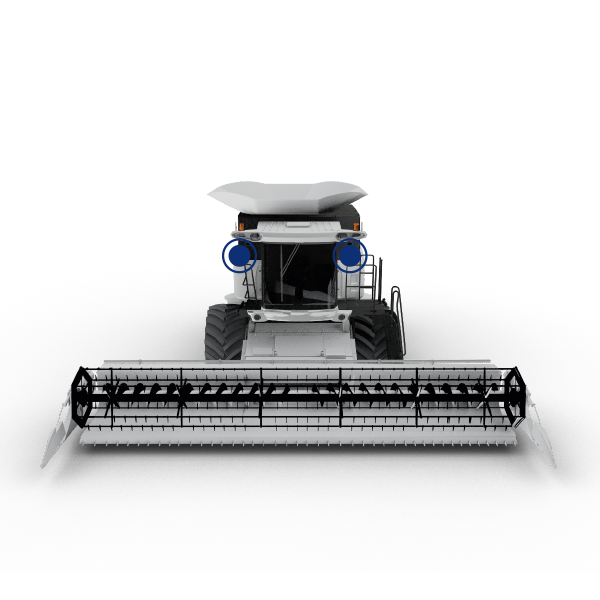

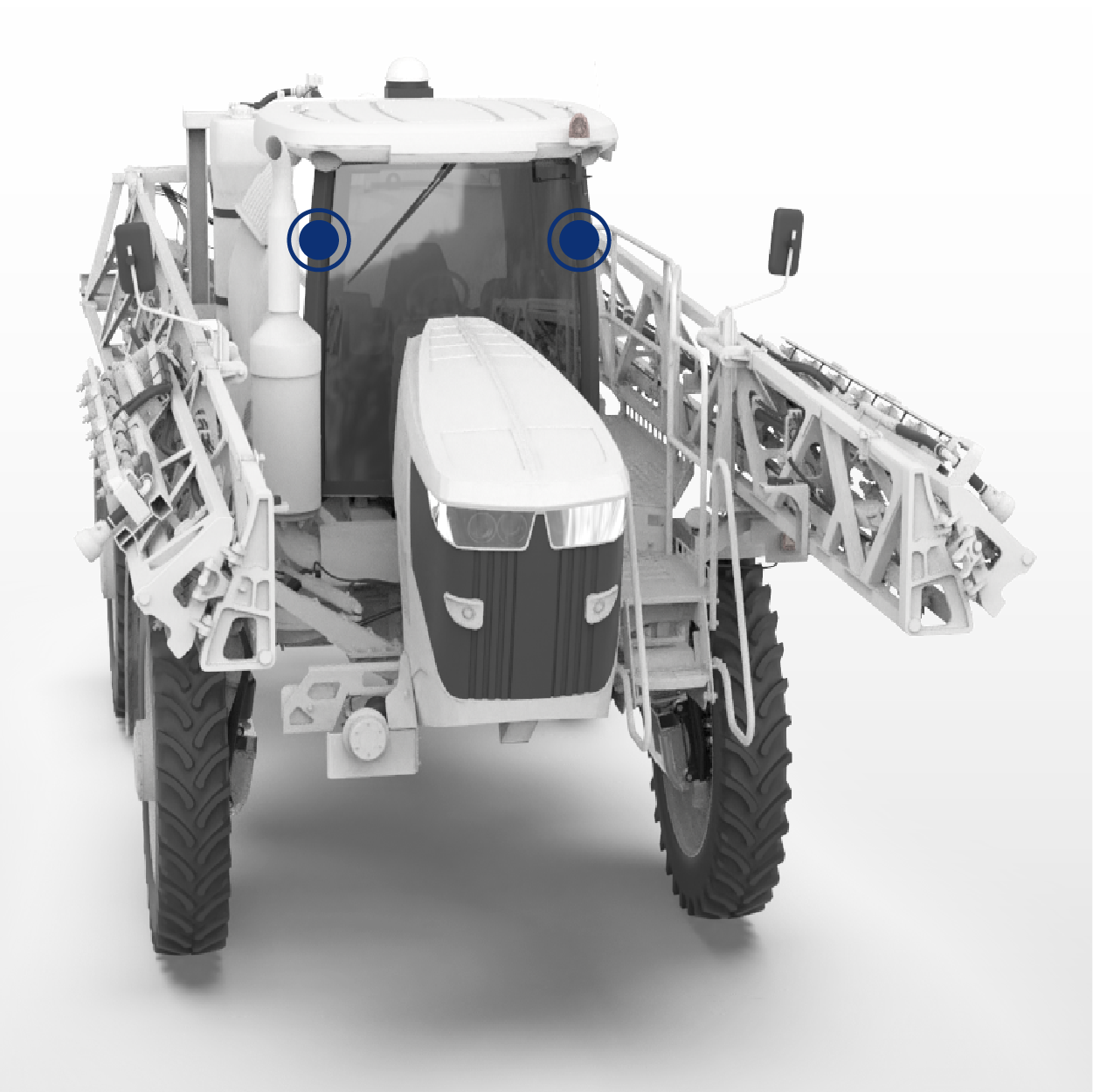

Field of vision in front of the farm tractor

MEKRA Lang offers a front view system which meets the requirements of the DLG directive for front-mounted implements. It consists of two cameras, cables and monitors.

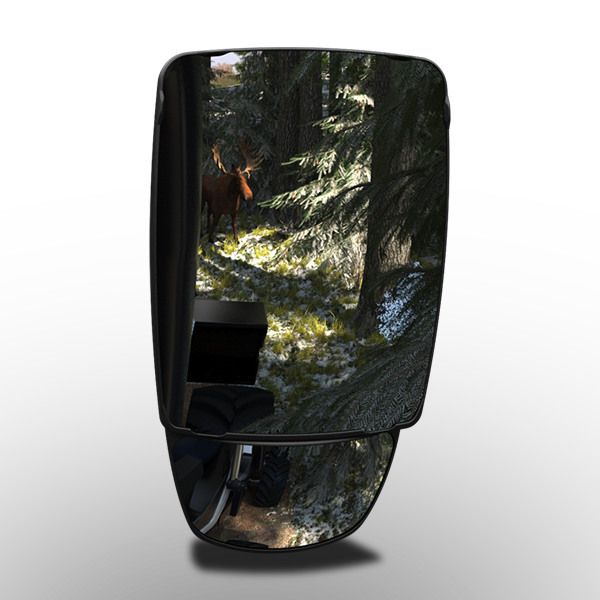

As additional convenience features for farm tractors, a rear view camera or a wireless system can be used. (Video)

All-around Vision Solution

MEKRA’s surround view system is another very helpful visibility tool. It displays various camera images on the monitor to provide the driver with the required situational visibility information.

Requirements

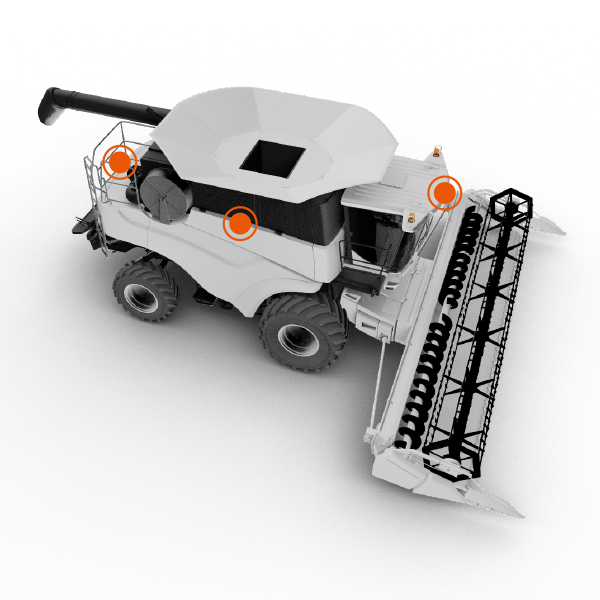

In addition to the standards ISO 5721-2, ISO 21495 and ISO 5721-3 there are country-specific regulations all of which are met by our mirror and camera monitor systems.

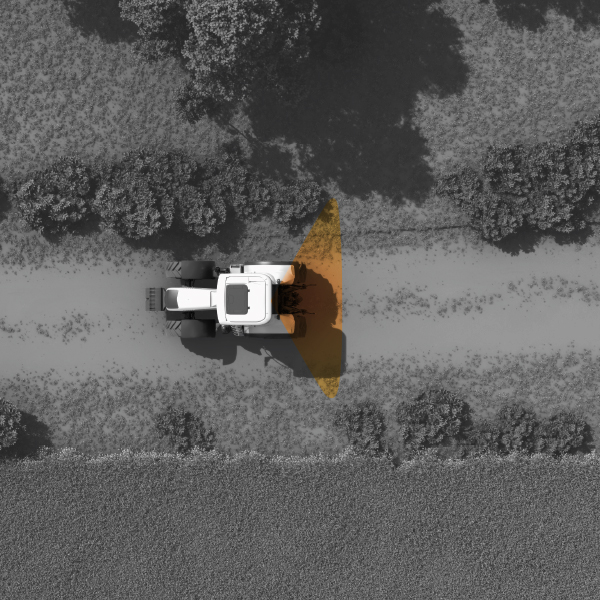

The statutory fields of view represent minimum requirements. The MEKRA fields of vision shown in ideal-typical representation may vary depending on vehicle size, shape, and mounting location. They do, however, always meet the legal minimum requirements.

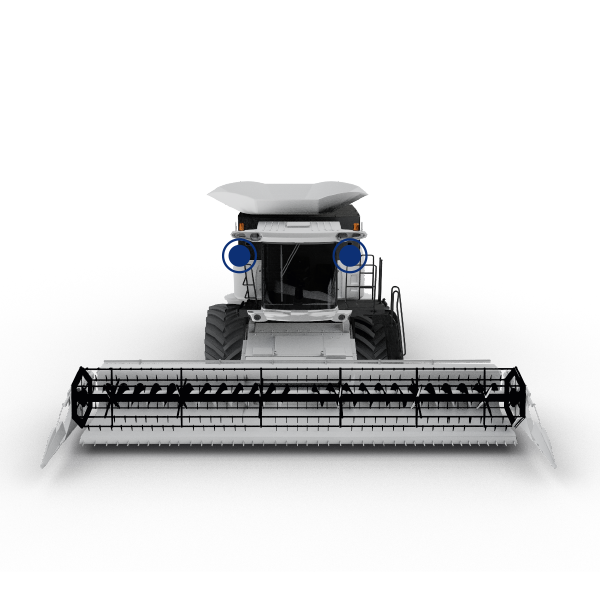

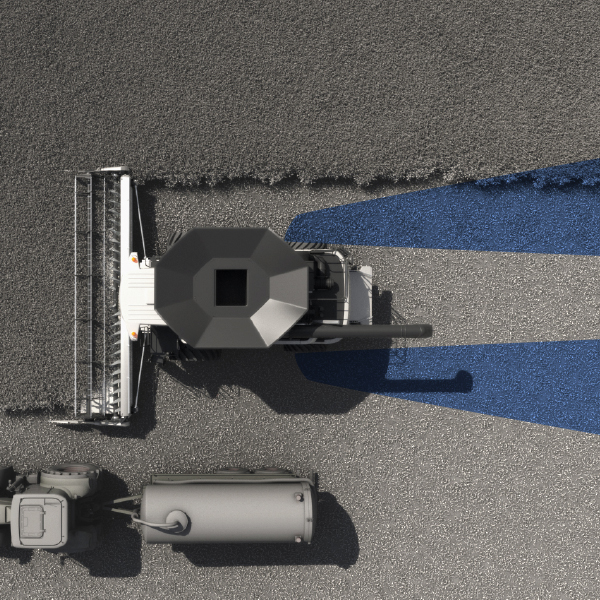

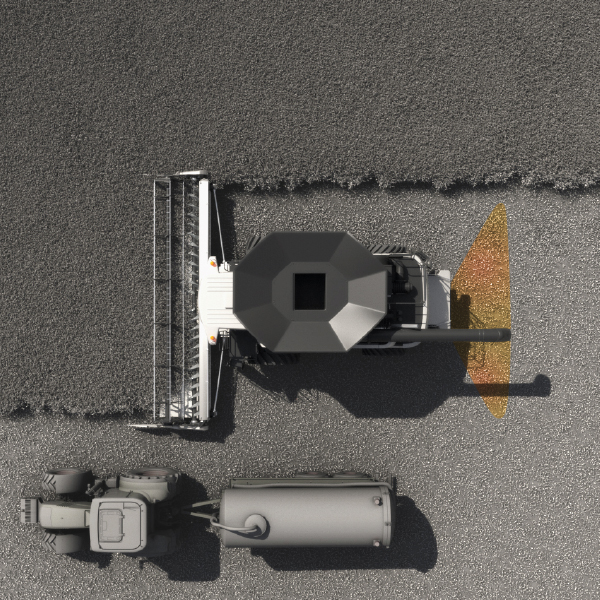

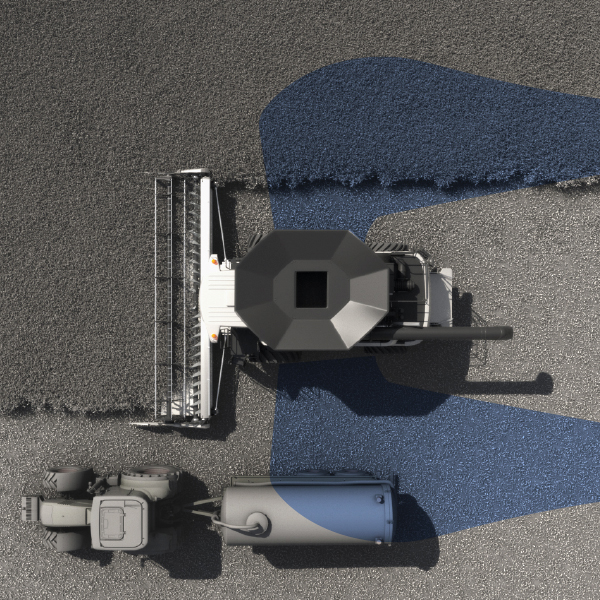

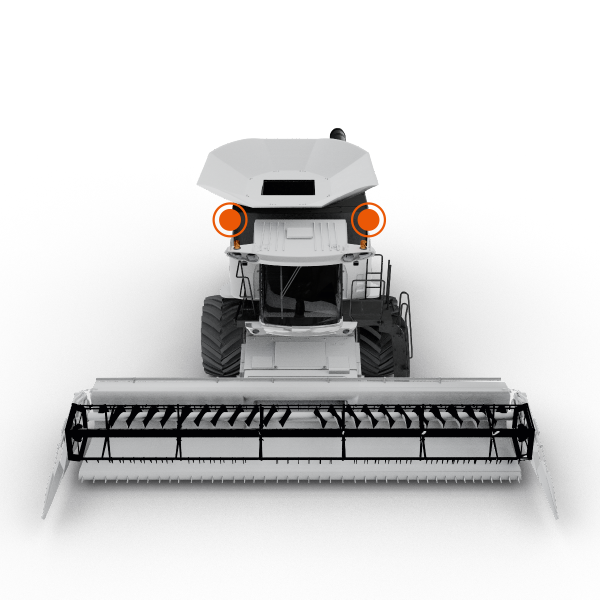

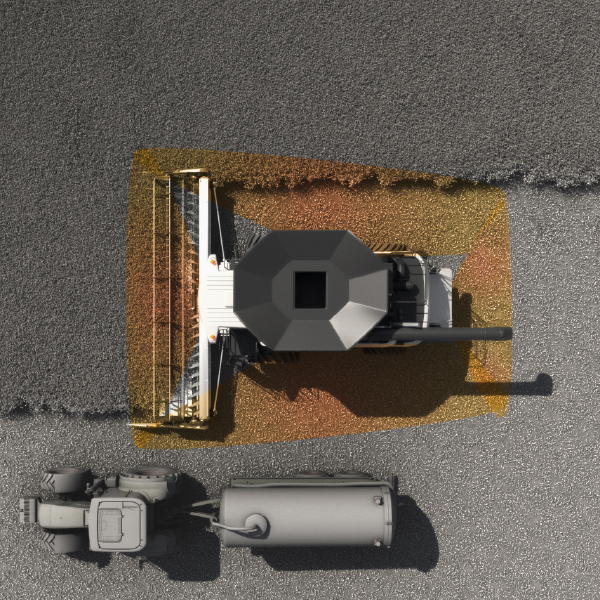

Field of vision behind the harvester

The field of vision behind the harvester is located one meter above the ground. It starts four meters behind the so-called “seat index point” (SIP) at a width of one meter directed outwards from the outer vehicle edge. The length is an additional 26 meters towards the back, the width thereby extending to five meters. From this point the horizon still has to be visible.

Mirror Solution

A traditional solution would be a so-called main mirror with a radius of curvature of 1200 mm and a close-proximity mirror with a radius of curvature of 300 mm.

We offer this type of mirror combination (e.g. no. 1036) in a number of configurations, including heated and/or manually or electrically adjustable.

Camera Solution

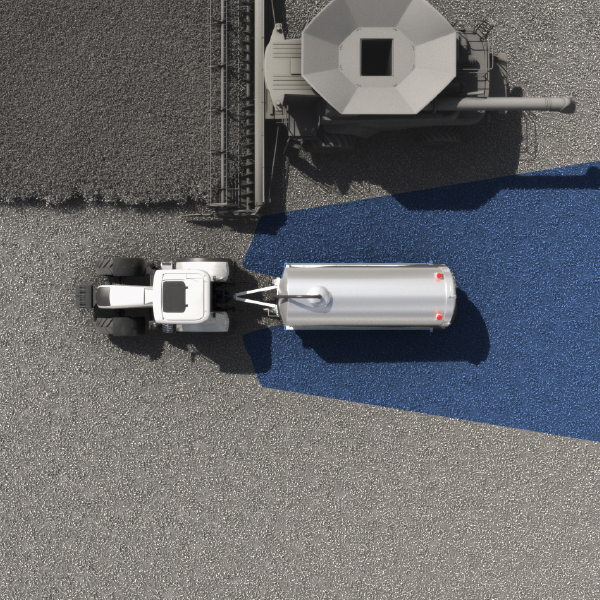

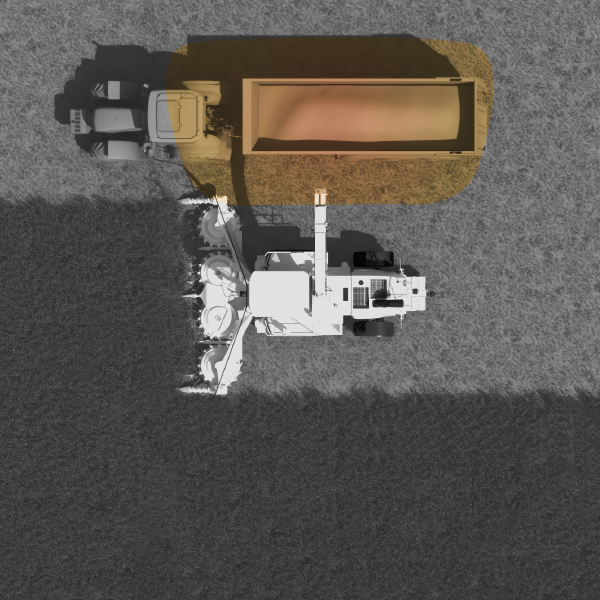

Field of vision to the side of the harvester

This field of vision is one meter above the ground and starts 0.5 m from the outermost vehicle outline. At eye point height it then extends by 1.75 m towards the back and by 1 m to the front. It is 1.5 m towards the outside.

It is important to note that either 90 % of this field of vision must be visible directly or 100 % by a combination of direct and indirect vision.

Mirror Solution

MEKRA Lang has developed a variety of solutions to meet these requirements.

Among other options, the 1009 modular mirror or the 1036 combination mirror can be used.

Camera Solution

Another innovative solution is capturing the field of vision using a camera. It can be attached to the 1009 modular mirror as an add-on.

All-around Vision Solutions

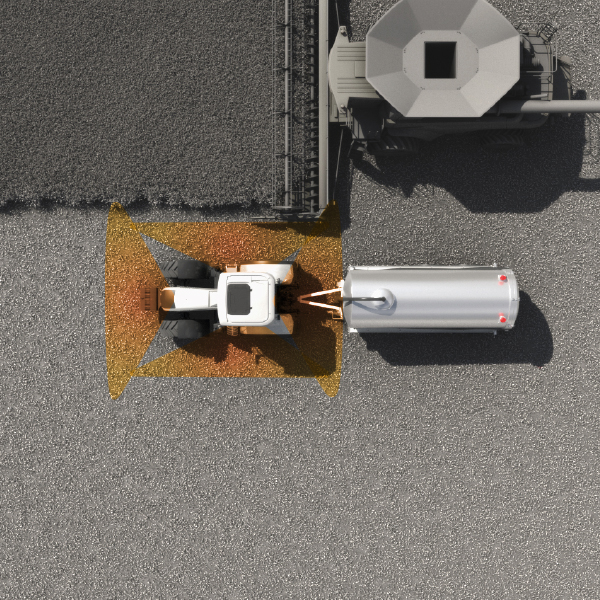

To meet the requirements set forth by ISO 21495, the main mirror, close-proximity mirror and an additional wide-angle mirror can be combined with a rear view camera.

ISO 21495 refers to a close-proximity assessment of 0.5 m around the vehicle outline using a specific test object.

MEKRA’s surround view system is another very helpful visibility tool. It displays various camera images on the monitor to provide the driver with the required situational visibility information.

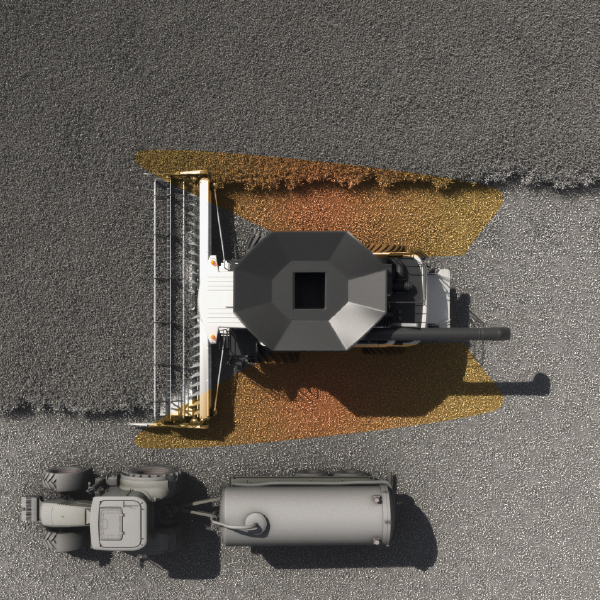

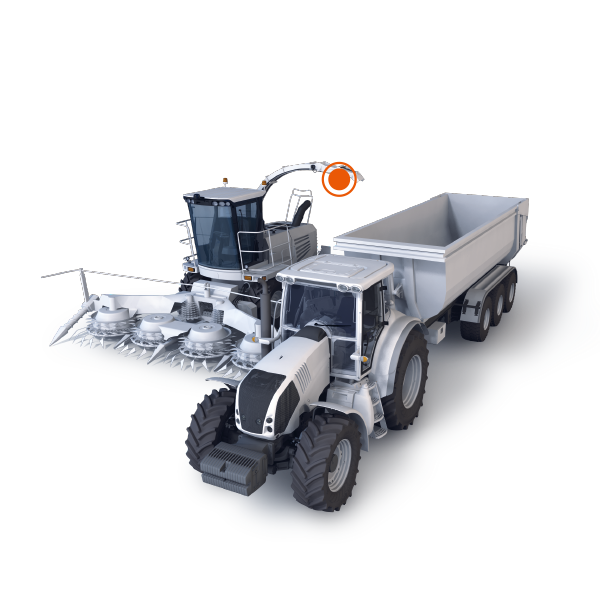

Work Area Monitoring

Additional convenience features for harvesters can include cameras for monitoring work processes. For example a grain tank camera or a transfer camera connected to a wireless system allows the operator to see the fill level of the trailer driving alongside the harvester.

Requirements

Each country has its own specific field-of-vision requirements which are all met by our mirror and/or camera monitor systems.

The statutory fields of vision represent minimum requirements. The MEKRA fields of vision shown in ideal-typical representation may vary depending on vehicle size, shape, and mounting location. They do, however, always meet the legal minimum requirements.

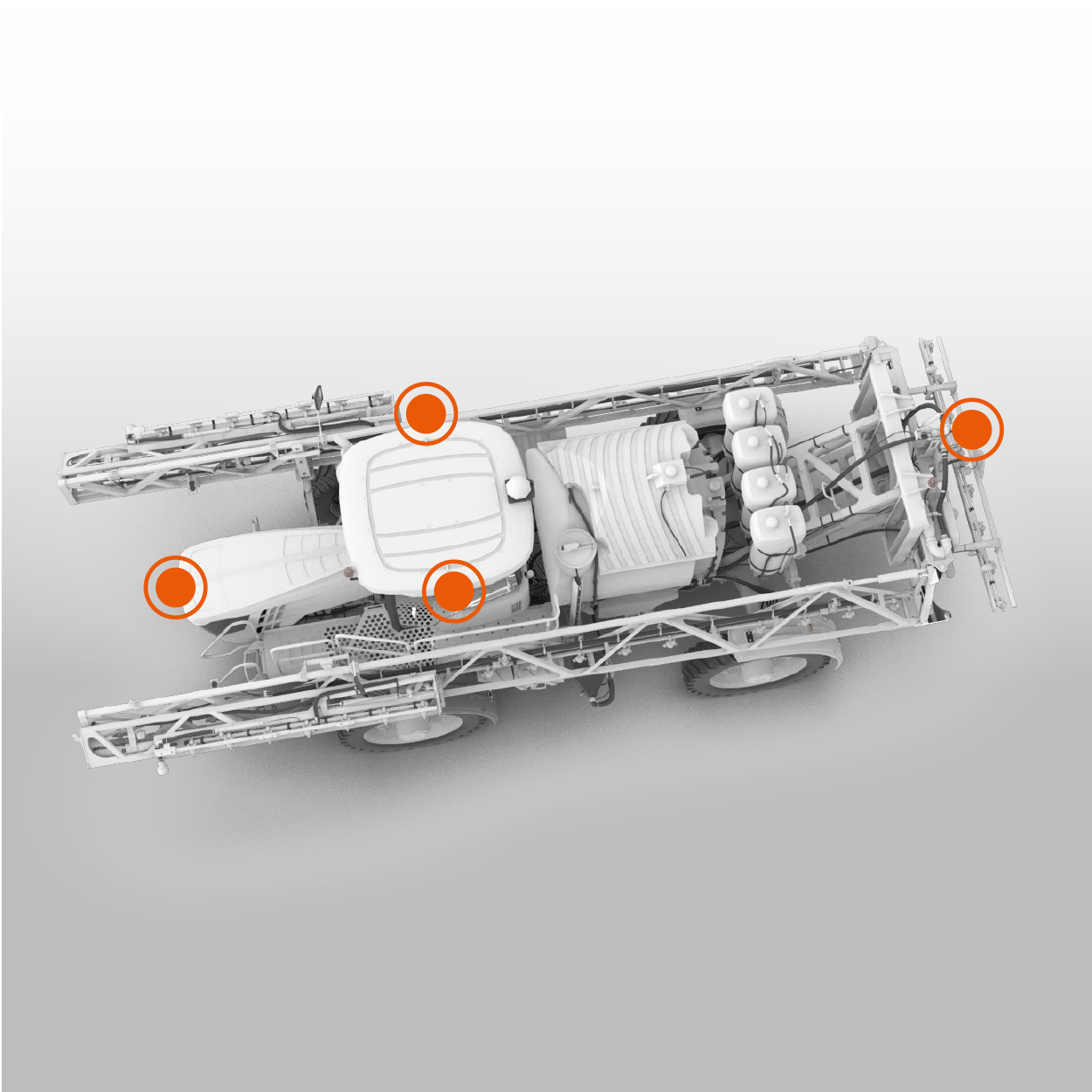

Mirror Solution

MEKRA Lang develops tailored solutions based on the specific vehicle geometry. The solutions not only include mirrors but also the corresponding mounting systems.

To comply with the relevant field-of-vision requirements, we have developed the 1010 compact mirror as well as the 1009 modular mirror with auxiliary mirror.

The following image shows our mirror solutions in connection with the indicated fields of vision.

All-around Vision Solution

MEKRA Lang has developed camera monitor systems which can withstand the extremely rough work and environmental conditions typically found in self-propelled machine operations.

To meet the demands of the various conditions, we have developed the 1301 camera, the standard MEKRA monitor and the surround-view monitor.

The following image shows our camera monitor solutions in connection with the indicated fields of vision.

Requirements

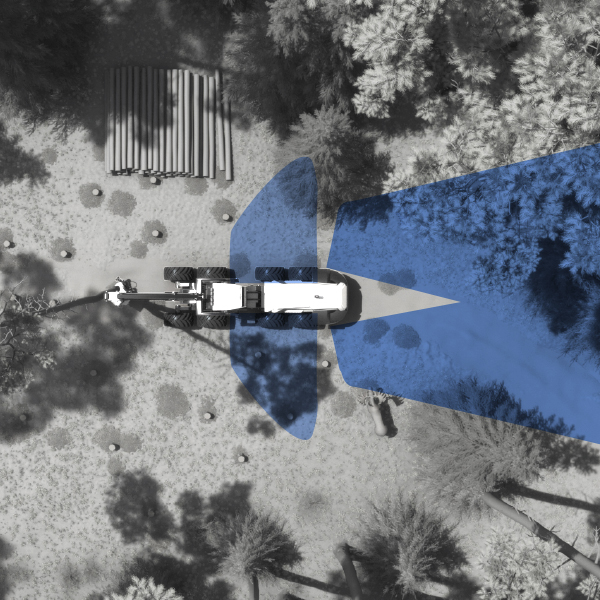

Each country has its own specific field-of-vision requirements which are all met by our mirror and/or camera monitor systems.

The statutory fields of vision represent minimum requirements. The MEKRA fields of vision shown in ideal-typical representation may vary depending on vehicle size, shape, and mounting location. They do, however, always meet the legal minimum requirements.

Mirror Solution

MEKRA Lang develops tailored solutions based on the specific vehicle geometry. The solutions not only include mirrors but also the corresponding mounting systems.

To comply with the relevant field-of-vision requirements, we have developed the 1010 compact mirror as well as the 1009 modular mirror with auxiliary mirror.

The following image shows our mirror solutions in connection with the indicated fields of vision.

All-around Vision Solution

MEKRA Lang

has developed rugged camera monitor systems, including the 1301 camera, the standard MEKRA monitor and the surround-view monitor, which can withstand the extremely rough work and environmental conditions typically found in forestry operations.